Single Point Mooring (SPM) systems are critical components in the oil and gas industries. Their flexibility, efficiency, and capability to operate in shallow and deep water make them indispensable for safe cargo transfer. As technology continues to develop, SPM systems will likely become even more efficient and environmentally friendly, further enhancing their critical role in global trade

What is Single Point Mooring?

Single Point Mooring refers to a buoy system that allows a vessel to be anchored at a single point while being able to rotate around that point. This design enables vessels to safely moor in deep waters without the need for traditional mooring systems, which can be cumbersome and less flexible.

SPM systems consist of several key components:

- Buoy Body: The floating structure that serves as the mooring point.

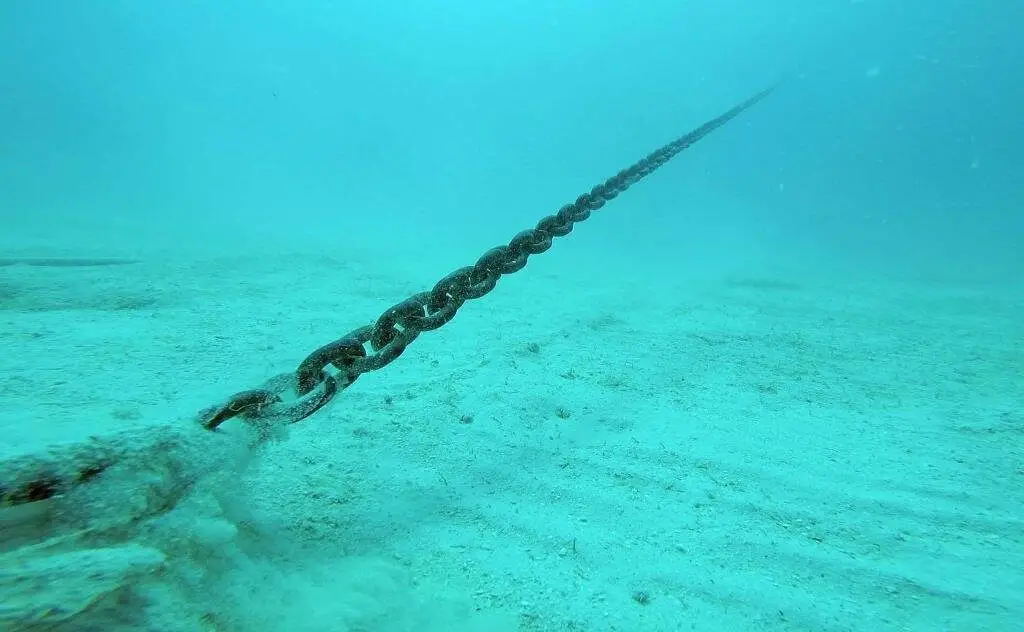

- Mooring Chains and Anchor Piles or Drag Anchors: Heavy mooring chains and anchor piles or drag anchors secure the buoy to the seabed.

- Flexible Hose: The connection between buoy and tanker is established by floating hose strings which allowing for the transfer of liquids such as crude oil, gas and condensate.

- Turntable/Turret

- PLEM (Pipe Line End Manifold)

- Subsea Hoses

- Main Bearing

- Product Swivel

- Flexible Expansion Joint

- Chain Stopper

- Winch

- HPU

- Telemetry and Navigation Aids

Advantages of SPM Systems

SPM systems offer numerous benefits over traditional mooring techniques:

1. Flexibility

The ability of vessels to rotate around a single point allows for better alignment with prevailing wind and sea conditions. This flexibility minimizes stress on the mooring lines and enhances safety during operations.

2. Deep Water Capability

SPM systems can be deployed in deep waters where conventional mooring systems may not be feasible. This capability is particularly important in offshore oil and gas exploration, where drilling rigs are often located far from shore.

3. Reduced Environmental Impact

By utilizing SPM systems, the need for extensive underwater infrastructure is minimized, reducing the environmental footprint associated with marine operations.

4. Efficient Cargo Transfer

SPM systems facilitate quick and efficient transfer of liquids, which is essential for operations in industries like oil and gas. The flexible hoses allow for safe and effective loading and unloading.

Applications of SPM

Single Point Mooring systems are widely used across various sectors:

Oil and Gas Industry

In the oil and gas sector, SPMs are primarily used for loading and unloading crude oil and condensate from tankers at offshore production facilities. They enable efficient transfer operations while minimizing risks associated with rough sea conditions.

Bulk Liquid Storage

SPM systems are also employed in the storage and transfer of bulk liquids such as chemicals and liquefied natural gas (LNG). Their flexibility and efficiency make them ideal for these applications.

Marine Terminals

Many marine terminals utilize SPM systems to accommodate large vessels that cannot dock at traditional piers due to depth restrictions. This allows for greater versatility in shipping operations.

Challenges and Considerations

While SPM systems offer significant advantages, they also come with challenges:

1. Maintenance

Regular inspections and maintenance are crucial to ensure the integrity and safety of the mooring system. Failure to maintain SPM can lead to catastrophic failures, resulting in environmental disasters or loss of life.

2. Weather Conditions

Extreme weather can impact operations, requiring careful planning and monitoring. Operators must be prepared for sudden changes in weather that could affect vessel stability.

3. Regulatory Compliance

Operators must adhere to strict regulations governing marine operations to ensure environmental protection and safety. This includes compliance with international maritime laws and local regulations.

The Mechanism of SPM Operations

Understanding how SPM systems work is essential for appreciating their importance in maritime logistics.

Operational Workflow

Once installed, the operational workflow involves:

– Vessel Approach: The vessel approaches the buoy and secures itself using a series of lines.

– Cargo Transfer: Liquid cargo is transferred through flexible hoses.

– Monitoring: Continuous monitoring ensures safety during operations, taking into account weather conditions and vessel movements.

Future Trends in SPM Technology

As technology evolves, so do SPM systems. Here are some emerging trends:

1. Automation

The integration of automated systems for monitoring and controlling SPM operations is on the rise. Automation enhances safety by reducing human error.

2. Eco-Friendly Materials

There is a growing emphasis on using eco-friendly materials in constructing SPM systems to minimize environmental impact.

3. Advanced Monitoring Systems

The development of advanced monitoring technologies, including AI and IoT, allows for real-time data collection and analysis, improving operational efficiency.